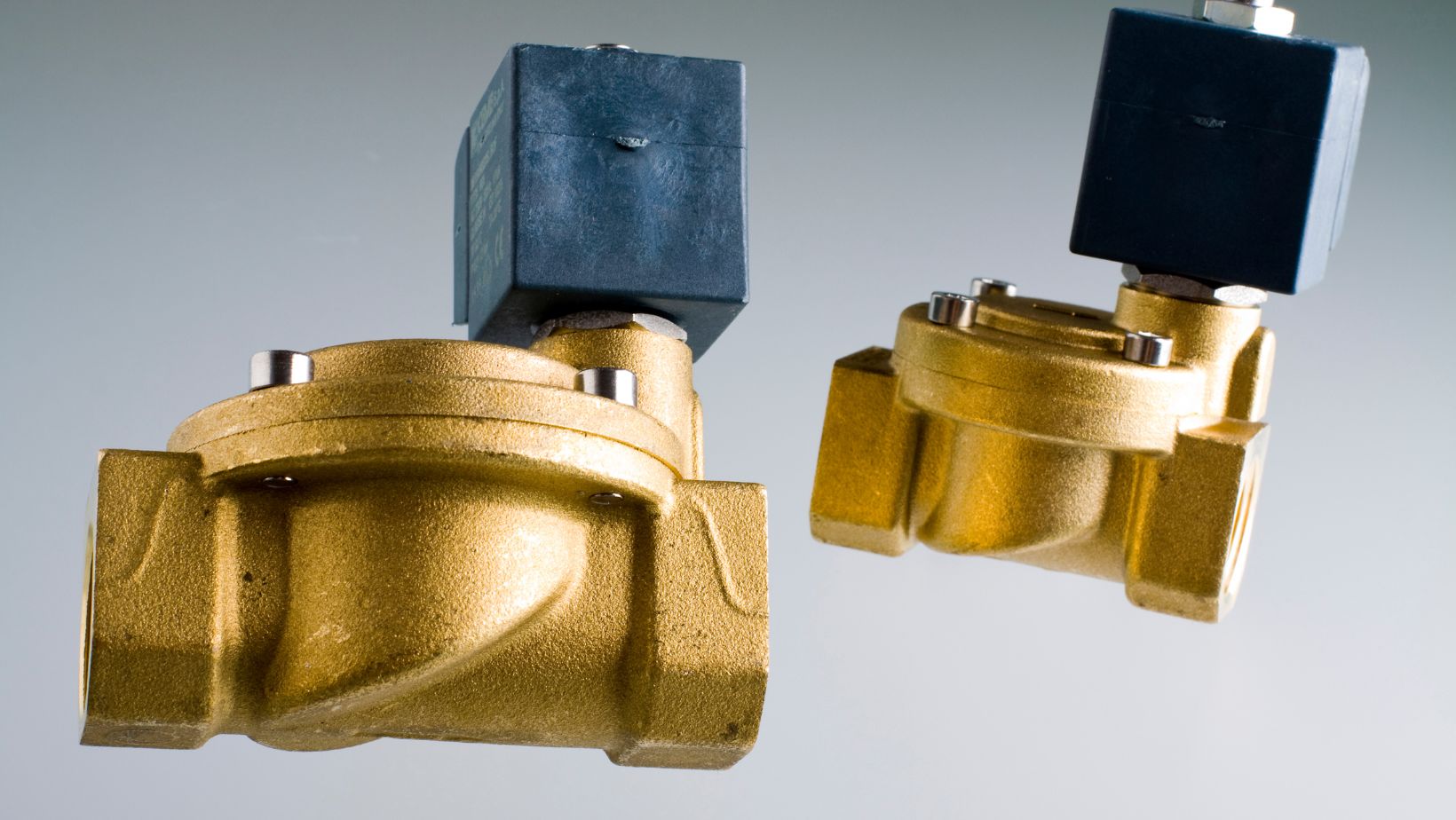

Solenoid valves are electromechanical devices that precisely control the flow of fluids, be it liquids or gases. At their core, they operate on a simple yet ingenious principle: an electromagnetic coil generates a magnetic field when energized, which actuates a movable element within the valve body. This movement, typically a plunger or spool, directly or indirectly controls fluid passage through the valve’s orifice.

A wide variety of industries find solenoid valves to be important. They are essential from the comfort of our homes to complex manufacturing processes. They enable accurate material handling and automate complex assembly lines in production. Solenoid valves are used extensively in the automotive industry for braking, gearbox control, and fuel injection. They control temperature and airflow in the HVAC sector to guarantee ideal environmental conditions. Additionally, solenoid valves are used in water treatment facilities to regulate chemical flow, ensuring effective and safe water distribution.

Solenoid valves are widely used because of their inherent benefits. Their outstanding dependability reduces maintenance needs and downtime. Solenoid valves are also incredibly flexible, making it possible to integrate them easily into various control systems. Their ease of automation improves operational effectiveness and permits accurate fluid flow regulation, which results in considerable energy savings and a lessened environmental effect.

Burkert, a renowned global leader in fluid control technology, offers a comprehensive range of high-quality solenoid valves. Known for their innovation and precision engineering, Burkert Solenoid valves are designed to meet the most demanding applications across industries, their portfolio includes a broad range of valve types, such as direct-acting, pilot-operated, 2-way, 3-way, and many more. Their commitment to quality and customer satisfaction has established them as a trusted partner in fluid control solutions worldwide.

Classification of Solenoid Valves

Solenoid valves exhibit diverse configurations, each tailored to specific operational requirements. A comprehensive understanding of these classifications is crucial for selecting the optimal valve for a given application.

By Function

Normally Closed (NC): As the name suggests, an NC solenoid valve remains closed in its de-energized state. When an electrical signal is applied, the solenoid actuates, opening the valve to allow fluid flow. NC valves find widespread application in safety-critical systems, such as emergency shut-off valves, where preventing unintended fluid release is paramount. They also play a vital role in avoiding backflow in certain applications.

Normally Open (NO): In contrast, an NO solenoid valve is open in its de-energized state. Applying an electrical signal causes the valve to close, halting fluid flow. NO valves are commonly employed in applications requiring rapid fluid flow initiation, such as quick-opening valves in pneumatic cylinders or emergency release valves.

By Construction

Direct-Acting: In direct-acting valves, the solenoid’s electromagnetic force directly acts upon the valve core, moving it to open or close the fluid passage. This design offers simplicity and a fast response time. However, direct-acting valves may require higher power consumption, particularly for larger valves or those operating against significant back pressure.

Pilot-Operated: Pilot-operated valves utilize a two-stage mechanism. The solenoid actuates a small pilot valve, which controls the flow of a pressurized fluid to operate the main valve. This design offers several advantages, including lower power consumption and the ability to handle higher flow rates. However, pilot-operated valves can be more complex and may exhibit a slightly slower response time than direct-acting valves.

By Number of Ports

2-Way: 2-way valves possess two ports: an inlet and an outlet. These valves provide simple on/off control, allowing or restricting fluid flow.

3-Way: 3-way valves feature three ports: an inlet, an outlet, and a common or exhaust port. These valves offer greater versatility, enabling functions such as switching between two fluid sources or diverting flow to different destinations.

4-Way: 4-way valves have four ports: two inlets and two outlets. These valves are typically used to control the direction of fluid flow, such as in double-acting cylinders, where they control both the extend and retract motions.

Key Considerations for Selecting Solenoid Valves

Selecting the appropriate solenoid valve for a given application requires careful consideration of several critical factors.

Flow Rate and Pressure

The valve’s flow capacity must be adequately sized to meet the system’s demands. Insufficient flow capacity can lead to inadequate performance or even system damage. Conversely, oversizing the valve can result in unnecessary costs and energy consumption. Similarly, the valve’s pressure rating must exceed the maximum operating pressure of the system to ensure safe and reliable operation.

Fluid Type

The compatibility of the valve’s internal components with the fluid being handled is paramount. Factors such as corrosion resistance, chemical compatibility, and the fluid’s viscosity must be carefully evaluated. For example, valves handling aggressive chemicals may require specialized materials like stainless steel or exotic alloys.

Voltage and Power Supply

Solenoid valves operate on specific voltage levels (e.g., 12V DC, 24V DC, 110V AC). It is essential to ensure compatibility with the available power supply. Additionally, the power consumption of the valve should be considered to avoid overloading circuits or exceeding the capacity of power sources.

Operating Environment

The operating environment can significantly impact valve performance and longevity. Factors such as ambient temperature, humidity, vibration, and exposure to corrosive elements must be considered. Valves for harsh environments may require specialized coatings, seals, and construction materials.

Mounting Options

Mounting options vary depending on the application. Common options include in-line mounting, panel mounting, and manifold mounting. The chosen mounting method should ensure proper installation and accessibility for maintenance and minimize potential vibration or stress on the valve.

Safety and Reliability

Safety and reliability are paramount in any fluid power system. Consider incorporating pressure relief valves to protect the system from excessive pressure. Fail-safe mechanisms, which ensure the valve is safe in case of power loss or malfunction, are crucial in safety-critical applications.

By carefully considering these factors, engineers and technicians can select solenoid valves that optimize system performance, enhance reliability, and ensure safe and efficient operation.

Applications of Solenoid Valves

The versatility of solenoid valves has led to their widespread adoption across many industries.

- Industrial Automation: Solenoid valves are critical in automating various industrial processes. In manufacturing, they control the flow of fluids in assembly lines, facilitating precise material handling and enhancing production efficiency. They are integral components in robotic systems, enabling accurate and controlled movements.

- Hydraulic and Pneumatic Systems: In hydraulic and pneumatic systems, solenoid valves regulate the flow of fluids, enabling the control of machinery, robotics, and braking systems. They are essential components in heavy machinery, construction equipment, and aircraft, providing precise control over movement and force.

- HVAC Systems: Within HVAC systems, solenoid valves control the flow of refrigerants, water, and air, ensuring optimal temperature and humidity control. They are crucial components in heating, ventilation, and air conditioning units, regulating airflow and enabling precise temperature adjustments.

- Water Treatment: In water treatment plants, solenoid valves are vital in controlling the flow of chemicals, such as chlorine and other disinfectants. They also regulate water flow during filtration processes, ensuring the delivery of clean and safe drinking water.

- Automotive Industry: The automotive industry relies heavily on solenoid valves for various applications. They are integral components in fuel injection systems, precisely controlling the amount of fuel delivered to the engine. Solenoid valves also play a critical role in transmission control systems, enabling smooth and efficient gear shifts. Furthermore, they are essential for braking systems, facilitating precise and responsive performance.

In conclusion, solenoid valves represent a cornerstone of modern fluid control technology. Their diverse range of configurations, including normally closed and normally open valves, direct-acting and pilot-operated designs, and valves with varying numbers of ports, provide engineers with exceptional flexibility in system design. It is impossible to overestimate the significance of solenoid valves. They play a critical role in numerous industries, enabling automation, enhancing efficiency, and improving safety. From industrial manufacturing and automotive applications to HVAC systems and water treatment plants, solenoid valves contribute significantly to technological advancement and societal progress. Looking ahead, the future of solenoid valve technology holds immense promise. More resilient and long-lasting valves that can endure challenging conditions are being developed as a result of developments in materials science. Smart valves, equipped with integrated sensors and microprocessors, are poised to revolutionize fluid control by enabling real-time monitoring, predictive maintenance, and enhanced system intelligence. Furthermore, integrating solenoid valves with the Internet of Things (IoT) will facilitate remote monitoring, control, and diagnostics, paving the way for a new era of intelligent and interconnected fluid power systems. Engineers and technicians can effectively select and utilize these versatile components to optimize system performance, enhance efficiency, and drive innovation across various industries by understanding their fundamental principles, classifications, and applications.

More Stories

How Landscaping Businesses Can Cut Costs and Boost Cash Flow

5 Costly Mistakes After a Business Vehicle Crash

Bringing architectural ideas to life before they’re built