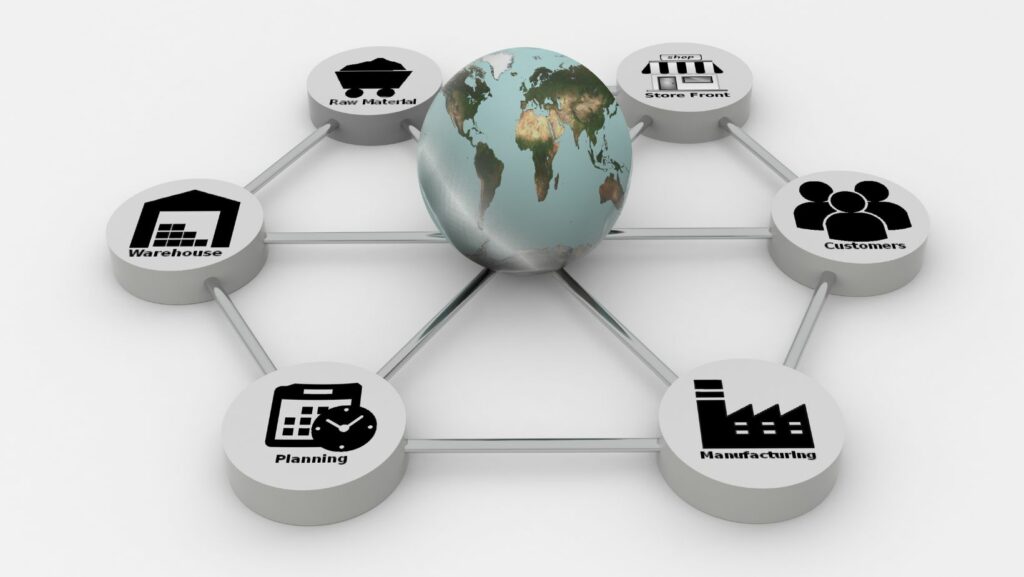

In today’s fast-paced global market, businesses strive to streamline operations and improve efficiency. A critical element of achieving these goals lies in enhancing supply chain visibility. But how can organizations keep track of every single item, shipment, and transaction in real-time? The answer may lie in leveraging the Internet of Things (IoT). IoT technology is revolutionizing industries by providing detailed insights into complex processes, including those involved in supply chain management.

I. Defining IoT and Its Components in the Supply Chain Context

-

Explanation of IoT Technology—Sensors, Devices, and Internet Connectivity

IoT refers to the network of physical objects — “things” — embedded with sensors, supply chain visibility software, and other technologies for the purpose of connecting and exchanging data with other devices and systems over the Internet. These objects range from ordinary household items to sophisticated industrial tools. In the context of supply chains, IoT devices can include GPS trackers, temperature sensors, and RFID tags, all designed to provide continuous, automatic updates on the status of goods and materials.

-

Key Components of IoT in Supply Chains: Devices, Networks, and Platforms

The three pillars of IoT in supply chain management include devices (sensors and trackers), networks (the communication infrastructure that connects these devices), and platforms (the software systems that analyze and present the data). These components work together to create a seamless flow of information across the entire supply chain. Devices collect data, networks transmit it securely, and platforms interpret it to deliver actionable insights.

II. Benefits of IoT for Supply Chain Visibility

-

Enhanced Real-Time Tracking

IoT drastically improves the capacity for real-time tracking within supply chains. Sensors and devices provide continuous data on the location, condition, and movement of goods, whether they are traveling by land, sea, or air. This supply chain and data analytics is invaluable not only for tracking items but also for responding to delays, optimizing routes, and managing global freight management. Utilizing IoT for logistics data analysis can significantly enhance the decision-making process, ensuring that operations managers have the most current information at their fingertips.

-

Improved Inventory Management

IoT technology also plays a critical role in revolutionizing inventory management practices. Sensors can monitor stock levels and environmental conditions, sending alerts when supplies need to be reordered or conditions deviate from set parameters.

This kind of dynamic inventory management system minimizes the risks of overstocking or stockouts, optimizes warehouse space, and can trigger automated replenishment orders. As such, IoT integrates deeply with supply chain analytics data sets to predict and manage inventory more efficiently.

-

Operational Efficiency and Cost Reduction

By integrating IoT devices throughout the supply chain, companies can streamline operations and reduce overhead costs. Data collected from IoT devices help in identifying bottlenecks, predicting possible system failures, and suggesting improvements. Additionally, the automation of data collection reduces labor costs and minimizes errors associated with manual entries, thus enhancing overall operational efficiency. These optimizations are crucial in managing freight logistics services more effectively, thereby contributing to overall cost reduction.

III. Implementing IoT for Enhanced Supply Chain Visibility

-

Key Steps to IoT Integration

Implementing IoT in a supply chain requires a strategic approach. The first step is to identify key areas where IoT can add value, such as inventory tracking, global freight management, or shipment monitoring. Following this, selecting the right sensors and devices that fit the specific needs of these areas becomes essential. The next step involves choosing a robust network infrastructure that can handle large volumes of data securely. Finally, a platform must be selected to integrate with existing systems and provide intuitive, actionable insights from the IoT data.

-

Challenges and Solutions

While the benefits of IoT are undeniable, challenges must be addressed for successful implementation. These challenges can be broadly categorized into technical hurdles and strategic considerations. Here’s a breakdown of the key challenges and potential solutions, presented in a professional manner:

Technical Hurdles:

Interoperability: Achieving seamless interoperability between disparate devices, networks, and platforms from various vendors remains a significant challenge. Standardized data formats and communication protocols are crucial to ensure data can be exchanged and analyzed effectively across the entire supply chain ecosystem. Businesses can mitigate this by opting for solutions that are built on open standards and prioritize compatibility with existing freight management systems.

- Security: The vast network of interconnected devices creates an expanded attack surface for cyber threats. Robust security measures are essential to protect sensitive data from unauthorized access, manipulation, or breaches. Implementing secure authentication protocols, robust encryption techniques, and vulnerability management practices are fundamental. Additionally, continuous monitoring and updates are necessary to address evolving security threats.

- Data Integration and Management: The sheer volume of data generated by IoT devices can be overwhelming. Businesses need robust global freight management strategies to ensure data is stored, analyzed, and utilized effectively. Investing in data integration tools and personnel with expertise in data analytics is crucial to transform raw data into actionable insights.

- Network Connectivity: Reliable and secure network connectivity underpins the continuous flow of data. Businesses need to assess their existing network infrastructure and consider potential limitations, especially for geographically dispersed operations. Utilizing a combination of cellular networks, Wi-Fi, and satellite communication can ensure consistent connectivity across various locations.

Strategic Considerations:

- Cost-Benefit Analysis: Implementing an IoT solution can involve significant upfront costs for devices, network infrastructure, software platforms, and data management solutions. Businesses need to conduct a thorough cost-benefit analysis to ensure the return on investment (ROI) justifies the expenditure.

- Change Management: Transitioning to an IoT-powered supply chain necessitates a change in mindset and operational practices for employees. Training programs and clear communication strategies are essential to ensure workforce buy-in and adoption of new technologies.

- Skillset Development: Implementing and managing an IoT ecosystem requires a certain level of technical expertise. Businesses might need to invest in upskilling programs for existing employees or consider partnering with reputable IT service providers who possess expertise in IoT solutions.

Conclusion:

Despite these challenges, the potential benefits of IoT for achieving real-time supply chain visibility are substantial. Through meticulous planning, selection of appropriate freight management solutions, addressing technical hurdles, and establishing a well-defined implementation strategy, businesses can harness the power of IoT to create a more efficient, transparent, and cost-effective supply chain. As the technology matures and becomes more readily available, businesses that embrace IoT will be well-positioned to gain a competitive edge in the global marketplace.

More Stories

How Does Cloud-Based Claims Software Improve Accessibility for Adjusters: Key Benefits Explained

The True Future of AI Customer Support

Here’s Why Desktop PCs Are Still Popular