Laser engraving has emerged as a modern and precise method for creating detailed designs on various materials. From personalized gifts to intricate industrial markings, laser engraving is increasingly popular across diverse fields like art, manufacturing, and product customization. This guide provides a beginner’s overview of laser engraving technology and its applications, helping you understand the basics of this exciting field.

What is Laser Engraving Technology?

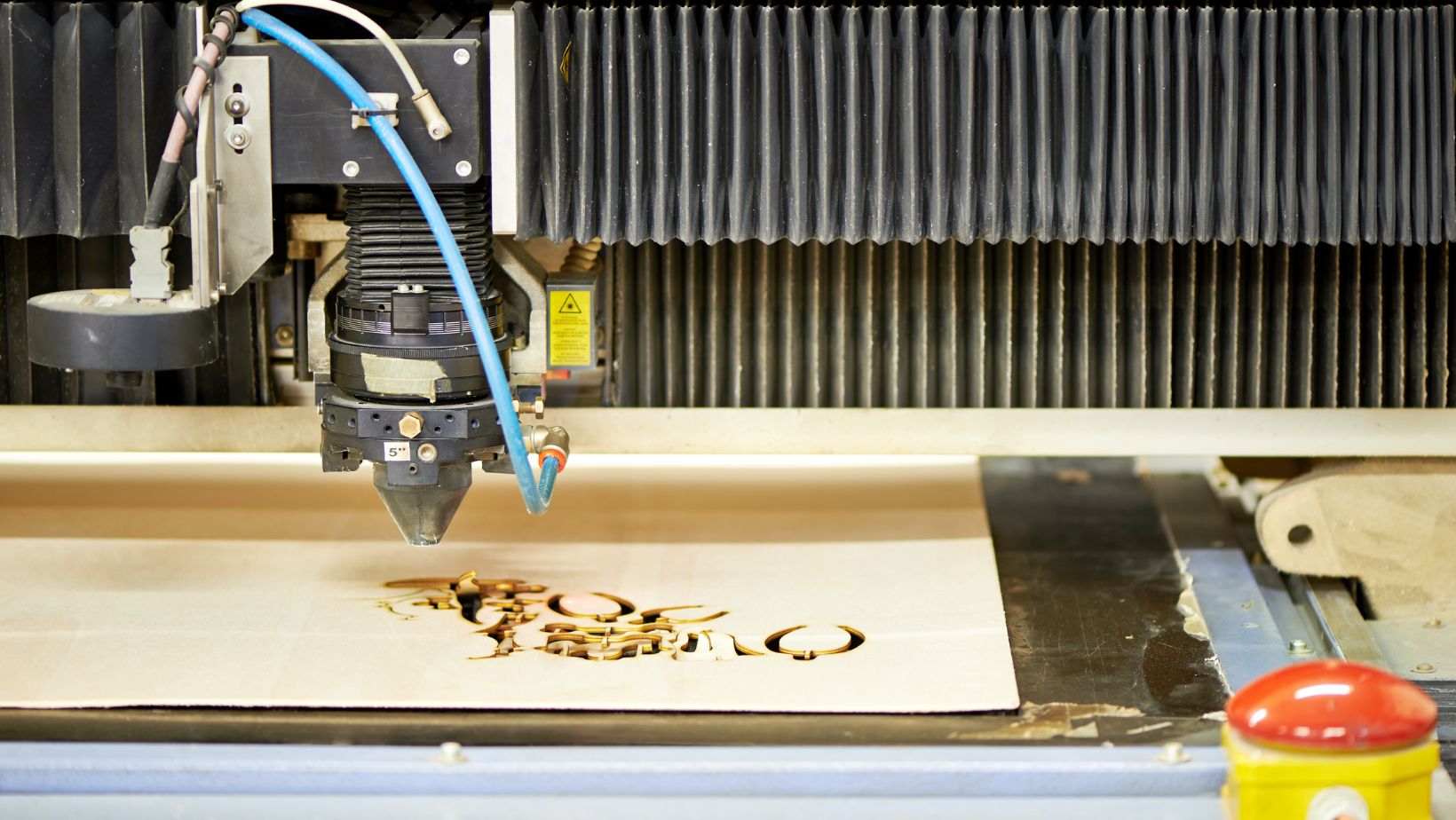

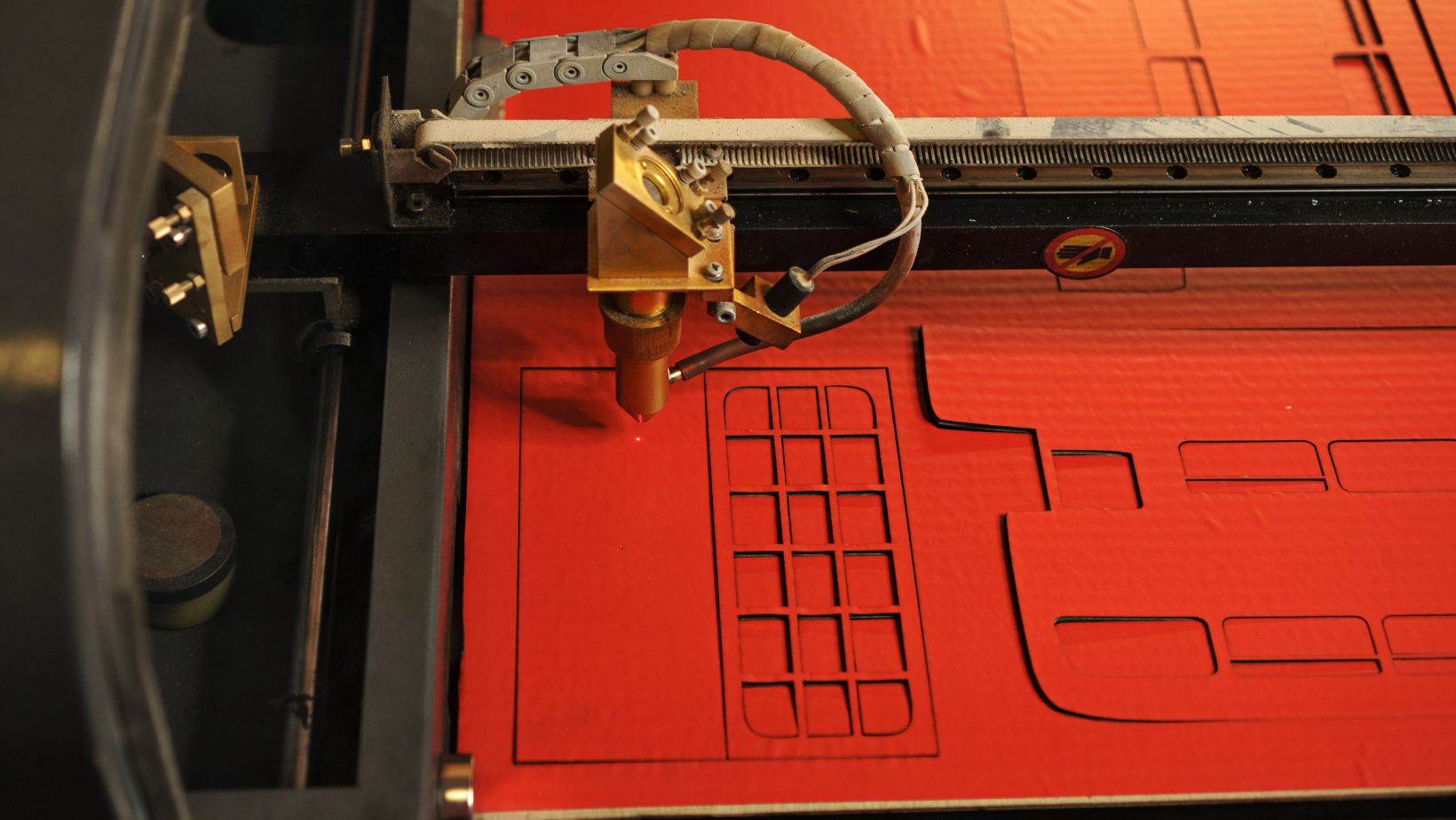

Laser engraving utilizes a high-intensity laser beam from a laser engraving machine to process material surfaces. The laser beam focuses on a small point, instantly evaporating, ablating, or melting the material to create engravings, patterns, or text. This is a non-contact process, offering a clean and precise way to mark or decorate a wide range of items. The path of the laser beam is controlled by a computer, allowing for the creation of intricate and accurate designs based on digital files.

Types of Laser Engravers

There are several types of laser engravers, each suited to different materials and applications:

- CO2 Lasers: These are versatile and commonly used for materials like wood, acrylic, glass, leather, and some fabrics. CO2 lasers use mirrors and lenses to amplify light rays and focus energy. The laser tube contains a mixture of CO2, helium, hydrogen, and nitrogen gas.

- Fiber Lasers: Ideal for high-precision marking and engraving on metals and other hard materials. Fiber lasers offer superior durability and speed compared to CO2 lasers, making them suitable for industrial applications.

- Diode Lasers: Suitable for engraving on plastics, leather, and some woods.

Advantages of Laser Engraving

Laser engraving offers several key advantages:

- High Precision and Accuracy: Laser engravers can create fine, detailed engravings.

- Speed and Efficiency: Laser engraving is generally a fast process, though speeds vary depending on the material and laser power.

- Material Diversity and Flexibility: Laser engraving can be used on a wide range of materials. CO2 lasers are suitable for wood, acrylic, leather, glass, metal, and plastic, while fiber lasers excel on metals.

- Automation and Repeatability: Computer-controlled operations allow for mass production and easy replication of designs.

- Intricate Designs and Customization: The technology allows for the creation of complex, detailed designs and personalized products.

Laser Engraving Project Ideas

The possibilities are vast. Here are a few ideas:

Home Decor:

- Laser-cut signs Design laser-cut signs for home decor and personalization.

- Clocks Create functional home decor by laser cutting clocks. You can find tutorials on OMTech’s YouTube channel.

- Picture frames Engrave wooden photo frames with names and special dates for personalized gifts.

- Coasters Engrave wooden coasters.

- Lamps Cut lamps from transparent, printed, or frosted acrylic.

Gifts and Awards:

- Personalized gifts Customize gifts by adding unique engravings.

- Custom laser-engraved plaques Design custom plaques for art, awards, or family photo walls.

- Personalized milestone memorabilia Offer customers custom engraved images.

Gardening:

- Plant-themed keychains and pins Laser engrave plant-themed keychains and pins.

- Plant marker garden stakes Organize your garden with custom garden stakes.

Choosing a Laser Engraver

To choose the right laser engraver, evaluate your business needs, including the types of materials you’ll be engraving, the size of the items, and how frequently you will use the machine. Consider these key factors:

- Budget: Determine how much you’re willing to invest.

- Materials: CO2 lasers work well with non-metallic materials like wood, glass, leather, and acrylic. Fiber lasers are suited for metals.

- Processing Area: Choose a working area size based on the size of your products. OMTech offers machines in various sizes. For example, one CO2 laser engraving machine has a processing area of 1300x900mm.

- Power Requirements: Different materials and thicknesses require different laser powers.

For engraving, 50W to 80W is suitable, while cutting requires 100W or more. OMTech offers CO2 laser engravers with power ranges from 40W to 150W.

- Ease of Use: Consider the user-friendliness of the interface and learning curve. Some machines have features like a Ruida digital controller with a digital display.

Safety Measures

Safety is paramount when operating a laser engraver:

- Protective Equipment: Always wear appropriate laser safety glasses.

- Ventilation: Use in a well-ventilated area with a properly connected exhaust system, as some materials produce hazardous fumes when engraved.

- Fire Safety: Keep flammable materials away and have fire extinguishers (suitable for electrical fires) readily available.

- Monitoring: Never leave a laser engraver unattended while it’s operating.

- Keep children and pets away from the laser engraving machine during operation.

- Know the location of the emergency stop switch and how it works.

- Only use materials that are suitable for laser engraving.

- Turn off the machine before cleaning or performing maintenance work.

- Read the instruction manual provided.

Conclusion

Laser engraving technology offers incredible precision, speed, and versatility, opening up a world of creative and practical applications. From personalizing gifts to streamlining manufacturing processes, it’s a powerful tool for both hobbyists and professionals. As you embark on your laser engraving journey, remember to prioritize safety, choose the right equipment for your needs, and let your imagination guide you. The possibilities are truly endless!

More Stories

Why Flexible Payment Options Like Klarna Matter for Financial Inclusion in Digital Entertainment

Things To Know Before Hiring Legal Support For Criminal Charges

Mobile Crypto Trading Platforms for 2026